Contract Manufacturing Capabilities

The global market for lyophilized biologics and pharmaceuticals is growing rapidly – along with that there are quite a few injectable products that need to be diluted prior to administration. A ready to use diluent prefilled syringe, provides you an opportunity to differentiate your product profile and also makes the compounding and administration user friendly for medical professionals and patients.

Benefits of prefilled diluent syringes:

- Less components and fewer steps in the administration process

- Precision, single-unit dosing helps in reducing waste of valuable Drug Product

- Helps in reducing risk of dosing error and improved patient safety

- Helps in compliance by Increasing user convenience

- Product differentiation from market competition

Medefil offers US FDA approved Sterile Diluents in plastic prefilled syringes:

- Sterile Water for Injection, USP (SWFI) [ANDA# 211188]

- Sodium Chloride Injection, USP, 0.9% (NaCl) [NDA# 202832]

The diluents are available in 6 mL and 12 mL syringe sizes and capability for custom fill from 1 mL to 10 mL. The labelling is with 0.2 mL graduation and flexibility to support fills like 2.2 mL, 3.4 mL.

Whatever your needs, Medefil will work directly with your team to help you create the right diluent program for your product. With Medefil’s established diluent prefilled syringe service you will benefit from a program that offers faster time-to-market, all-in-one simplicity and distinctive quality

- Fully automated mixing and formulation

- 2 X 3,200 Liters S.S. process vessels

- 2 X 1,680 Liters S.S. process vessels

- Syringe filling (1mL to 10mL Fill Volume)

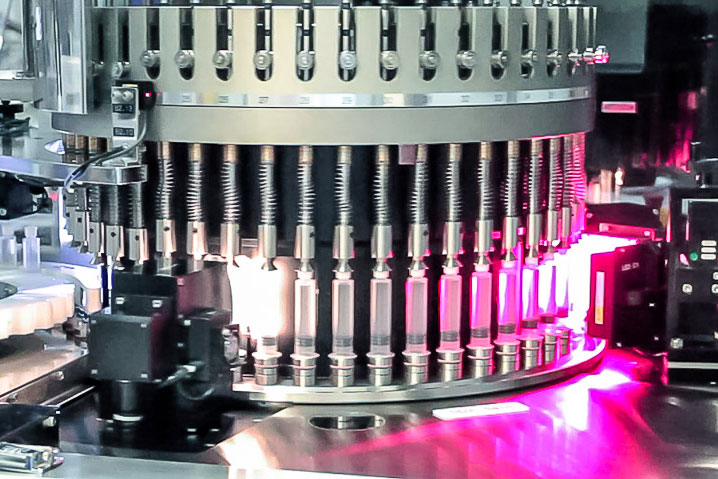

- 2 fully automated high speed syringe filling lines

- 315 syringes per minute

- Terminal sterilizers & automated handling system

- Robotic loading and unloading of trays and carts

- Steam-air mixture sterilizers

- Fully automated 100% syringe inspection system

- Presence or absence of tip cap

- Sub visible particulate matter

- Liquid in ribs

- Fully automated plunger rod insertion and labeling machine (vision capability)

- Check lot number and expiration date imprint

- Check presence of label and right placement of label on the syringe

- Fully automated pouching machine and dispenser box packaging process